Mobile Roll Mining Mill Of High Efficiency For Various Ores

.jpg)

Mills for minerals and ores Loesche

2025年4月2日 The dry milling of ore in LOESCHE vertical roller mills has shown significant process advantages, as well as economic and ecological benefits To demonstrate these a mobile oregrinding plant the OGPmobile has been 2019年4月16日 When compared to the products of conventional mills, the products of the Loesche mill demonstrated a significant improvement in flotation recoveries and grades, particularly for ores in which(PDF) LEARNING FROM OTHER INDUSTRIES; 2015年3月10日 Technical transformations of existing crushing process and equipment have developed to improve performance and efficiency, such as the application of highpressure Copper ore grinding in a mobile vertical roller mill pilot plant2001年10月1日 Recent research has shown, that the application of these vertical roller mills in dry grinding of ores and minerals can lead to significantly better recovery rates and higher Loesche vertical roller mills for the comminution of ores and minerals Fullymobile crushing station is a common crushing system offering solutions for crushing various ores and lumpsized materials for mine smelting industry, building material industry, roads, FullyMobile Crushing Station北方重工2025年3月31日 YGM High pressure Grinding Mill The YGM High Pressure Grinding Mill is an efficient and energysaving grinding solution designed for grinding various materials like Grinding Mills Grinding Mills HighEfficiency Grinding

.jpg)

Operational parameters affecting the vertical roller mill

2017年4月1日 Pilot plant test results with various ores showed that low energy consumption feature of vertical roller mills is applicable to the ore industry Grinding test results for zinc ore 2 天之前 Featuring a highly wearresistant roller surface, excellent crushing ratio, increased availability, cost and investment savings, and flexible configuration, the HPGR is capable of Ore Grinding Mill2024年11月4日 Loesche Vertical Roller Mill (VRM) is a revolutionary mineral processing tool that operates without water, capable of grinding rocks and minerals up to 50mm in a single pass Loesche Vertical Roller Mill for efficient processing2016年1月1日 For the past 100 years, the key element in the processing of gold ore has been the cyanidation processOver the years, steady improvements have occurred in equipment design; milling has evolved from stamp mills, through tube mills and ball mills to the large semiautogenous grinding (SAG) and fully autogenous grinding (FAG) circuits in modern gold Metallurgical Test Work: Gold Processing Options, Physical 2016年1月1日 South Africa, long known for tube mills (lowaspect semiautogenous mills), continues to contribute Highpressure grinding roll (HPGR) installations are now well established in the hardrock mining industry, including gold applications, and are now routinely considered as a comminution circuit minution Circuits for Gold Ore Processing ScienceDirect2015年3月10日 Vertical roller mills (VRM) have been used extensively for comminuting both cement raw materials and minerals like limestone, clinker, phosphate, manganese, magnesite, feldspar and titanium These mills combine crushing, grinding, classification and drying operations in one unit and have advantages over conventional machines and literature reports that 15% Copper ore grinding in a mobile vertical roller mill pilot plant

.jpg)

Magnetic Techniques for Mineral Processing ScienceDirect

2015年1月1日 SLon pulsating highgradient magnetic separator as shown in Figure 12 has been innovatively developing since 1986, based on the principle of pulsating highgradient magnetic separation, and it is now the mostly applied highgradient magnetic separator over the world, widely used for concentration of fine weakly magnetic ores such as hematite 2019年10月11日 The VRM, depending on the roller size, has a high reduction ratio; feed from 80 mm to 140 mm to a product of P80 at 75 µm in one pass, the mill is a closed circuit on its own having the comminution and classification of product in a single machine Sulphide coppergold ores are usually sorted by flotationVertical roller mills: The new leader in grinding technology2017年4月1日 Pilot plant test results with various ores showed that low energy consumption feature of vertical roller mills is applicable to the ore industry Grinding test results for zinc ore showed that it is possible to decrease the total grinding energy consumption from 2011 to 1140 kW h/t by using vertical roller mill instead of AG/SAGball mill Operational parameters affecting the vertical roller mill 2024年10月17日 Low energy consumption and media wear of only 0103 kg per ton of ore make our mills perfect for large scale mining as well as for small scale mining, laboratory mills, and lab grinding mills JXSC’s manufacturing plants cover an area of more than square meters, and are equipped with advanced production lines to meet the needs of Essential Guide to Grinding in Mineral Processing JXSC2024年1月13日 Figure 1 Showing electrical energy and embodied energy for different types of tumbling mills Adapted from [2] Recently, it was realised that highgrade ores are depleting fast and are almost Grinding Media in Ball MillsA Review ResearchGate2023年7月4日 It has the advantages of simple structure, stable operation, high efficiency, energy saving, and convenient maintenance It is widely applied in the crushing and grinding of metal and nonmetallic ores The product particle size can be less than 5 mm or finerRoller Mill SpringerLink

.jpg)

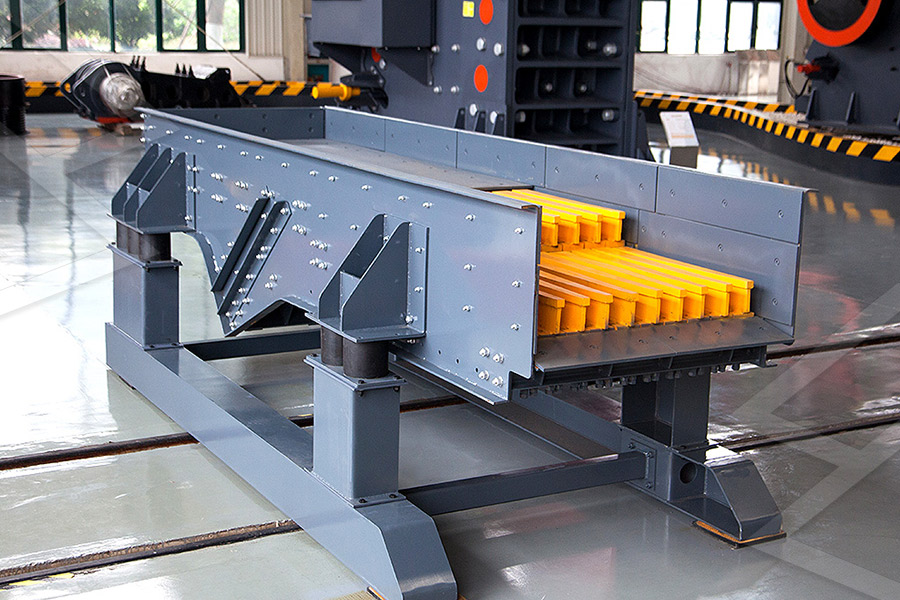

The Advantages and Applications of Double Roll Crushers in Mining

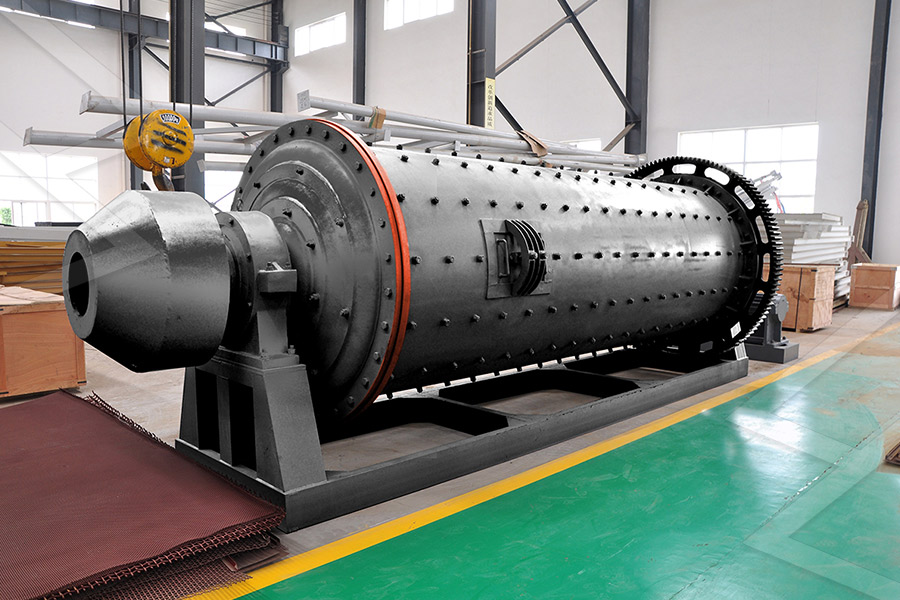

2023年2月23日 This article explores the benefits and uses of double roll crushers in the mining industry It provides an indepth analysis of the components, operating principles, and various applications of double roll crushers Additionally, it compares the advantages and limitations of double roll crushers with other types of crushers commonly used in mining operationsToothed Wheel Crusher 1Toothed wheel crusher is mainly used for rough chipping and second paragraphs of rock mite materials in various hardness (compressive strength ≤250MPa), such as brokenproof mine rocks, mining China Crusher Machine Manufacturers2012年6月1日 Typical examples are the various ores, minerals, limestone, etc efficiency of the ball mill and the economic assessment of the process control Hybrid HighPressure Roll Mill/Ball Mill (PDF) Grinding in Ball Mills: Modeling and 2025年4月3日 1832% Chrome Content Super High Chrome Iron Balls; 100mm160mm(465 inch) Large Size Ball Using for Big Ball Mill/ SemiAutogenous Mill(SAG Mill)Ball Mills 47 Manufacturers, Traders Suppliers2010年9月13日 Effects of High Pressure Grinding Rolls on PlatinumBearing Ores and the Flotation Response as Compared to the Conventional Ball Mill Three major PGM ore types from the Bushveld Complex of South Africa: Merensky, UG2 and Platreef were comminuted with the use of the high pressure grinding rolls (HPGR) The influence of the feed characteristics and Effects of High Pressure Grinding Rolls on PlatinumBearing Ores 2022年9月1日 The easiesttomine ores have already been exploited and the remaining ones are typically complex, low grade ores the feasibility of minetomill optimisation is high (Zhang and Luukkanen increasing the overall separation efficiency Various cyclonic separators and air classifiers have been used in numerous applications to separate a Towards waterless operations from mine to mill ScienceDirect

Advanced comminution modelling: Part 1 – Crushers

The McIvor review states that high pressure grinding rolls came into use in the cement industry during the 1990s, and also found acceptance in the diamond industry However, tests on base metals experienced serious wear problems and introduction into mineral processing required the development of roll surfaces with very high wear resistance2007年6月1日 Their results with various ores showed that a reduction in grindability by highpressure grinding rolls can be demonstrated both on lab and pilot plant scale Mining Magazine, 50 Google Scholar Bickert et al, 1996 The effect of ball size on the energy efficiency of hybrid highpressure roll mill/ball mill grinding Powder Technology Enhancement of energy efficiency for mechanical production of 2024年10月5日 Baichy’s ball mills are designed with energysaving features that reduce power consumption and enhance grinding efficiency The optimized design of the mill chamber, along with the use of highquality grinding media, ensures that energy is used efficiently throughout the grinding prehensive Guide to Ball Mills for Fine Material Grinding2025年4月3日 Sorting can help the progressive upgrade of ore concentration This enables the mill to process at a very high concentration, without gangue driving down the average The sorting criteria should also be integrated with the mine plan and blast design to ensure only the right parts of the orebody are sent for blasting and sortingMining energygovau2 天之前 The ball mill is the crucial equipment for conducting pulverizing operations after materials are crushed, widely employed for crushing and grinding various ores or other grindable materials In general, it is preferable to utilize an overflow ball mill for fine ore grinding fineness and a grate ball mill for coarse grindingOre Grinding Mill2016年1月1日 Abrasive ores such as gold and copper produce high wear rates of about 120µm/hr mill efficiency, minerals liberation and grinding rate is used in mining, crushing plants, as mill liners (PDF) A comparison of wear rates of ball mill

.jpg)

Gold Ore Processing Solution Eastman Rock

The GP (singlecylinder) hydraulic cone crusher is widely used in the medium and fine crushing process of iron ore, copper ore, gold ore and other metal mines Eastman singlecylinder hydraulic cone crusher is a highefficiency crusher The machine utilizes a combination of friction, impact, and shear forces to crush solid materials, ensuring high grinding efficiency and low energy consumption Advantages of Wet Pan Mill One of the key advantages of the wet pan mill is its versatility in handling various types of ores, making it suitable for different mineral processing Efficient Wet Pan Mills for Gold and Stone Grinding2024年9月24日 in the mill all tests is 700 CC of the packed minus 6mesh roll product, and the number of grams occupying 700 CC is the unit test weight This weight is placed in the mill dry, ground for the number of revolutions estimated to be necessary, discharged, ant1 screened mechanically in three testingStandard Grindability Tests and Calculations 911 2024年4月27日 These features enhance the versatility and efficiency of mobile crushing plants for various applications 3 Versatile Crushing Capabilities Mobile crushing plants can handle a wide range of materials, including hard rocks, ores, and recycled concrete They are commonly used in construction, mining, quarrying, and recycling applicationsA Comprehensive Guide on Mining Crushing Equipment2025年2月20日 Cone Crushers for Crushing Applications The cone crusher is primarily designed for the crushing of midhard to very hard ores and rocks It is a highly favored stone crushing equipment, widely employed in the production of manufactured sand, aggregates, and mining activities This type of crusher is commonly used in the secondary and tertiary stagesPY Cone Crusher: Versatile Solutions for Hard Ores2014年2月1日 Analysis of published data has shown that overall relative mine and mill costs on average are not significantly different for hard rock mining operations in general, and constitute the bulk of the overall mine cost G A costs were found to occupy a much smaller proportion of the total mine cost compared with the mine and millMine operating costs and the potential impacts of energy and

CFB石灰石脱硫剂制备——磨机公众号12.8 推送案例(8)53.jpg)

Modelling SAG milling power and specific energy consumption including

2015年1月1日 The feed size distribution is also the implicit result of the ore competence (affecting blasting and crushing performance) This distribution affects the SAG mill load and the load affects directly the mill power and the efficiency of the mill operation (Van Nierop and Moys, 2001)If a SAG mill has been designed with a conventional power or specific energy model 2023年1月4日 advisable to subject these types of ores to grinding balls, which can withstand the higher energy that the ores possess (Yusupov et al, cations: 2007) interaction between grinding media and mineral in iii) The mill: Mill size and type, speed and discharge type are factors of the mill that need to beSelection of Grinding Media for Use in the Gold 2011年5月1日 Highpressure grinding rolls (HPGR) are an accepted, but continuously expanding, comminution technology The copper industry has a growing need to process harder ores with progressively lower (PDF) HPGR Comminution for Optimization of Copper Leaching 2016年1月1日 For the past 100 years, the key element in the processing of gold ore has been the cyanidation processOver the years, steady improvements have occurred in equipment design; milling has evolved from stamp mills, through tube mills and ball mills to the large semiautogenous grinding (SAG) and fully autogenous grinding (FAG) circuits in modern gold Metallurgical Test Work: Gold Processing Options, Physical 2016年1月1日 South Africa, long known for tube mills (lowaspect semiautogenous mills), continues to contribute Highpressure grinding roll (HPGR) installations are now well established in the hardrock mining industry, including gold applications, and are now routinely considered as a comminution circuit minution Circuits for Gold Ore Processing ScienceDirect2015年3月10日 Vertical roller mills (VRM) have been used extensively for comminuting both cement raw materials and minerals like limestone, clinker, phosphate, manganese, magnesite, feldspar and titanium These mills combine crushing, grinding, classification and drying operations in one unit and have advantages over conventional machines and literature reports that 15% Copper ore grinding in a mobile vertical roller mill pilot plant

Magnetic Techniques for Mineral Processing ScienceDirect

2015年1月1日 SLon pulsating highgradient magnetic separator as shown in Figure 12 has been innovatively developing since 1986, based on the principle of pulsating highgradient magnetic separation, and it is now the mostly applied highgradient magnetic separator over the world, widely used for concentration of fine weakly magnetic ores such as hematite 2019年10月11日 The VRM, depending on the roller size, has a high reduction ratio; feed from 80 mm to 140 mm to a product of P80 at 75 µm in one pass, the mill is a closed circuit on its own having the comminution and classification of product in a single machine Sulphide coppergold ores are usually sorted by flotationVertical roller mills: The new leader in grinding technology2017年4月1日 Pilot plant test results with various ores showed that low energy consumption feature of vertical roller mills is applicable to the ore industry Grinding test results for zinc ore showed that it is possible to decrease the total grinding energy consumption from 2011 to 1140 kW h/t by using vertical roller mill instead of AG/SAGball mill Operational parameters affecting the vertical roller mill 2024年10月17日 Low energy consumption and media wear of only 0103 kg per ton of ore make our mills perfect for large scale mining as well as for small scale mining, laboratory mills, and lab grinding mills JXSC’s manufacturing plants cover an area of more than square meters, and are equipped with advanced production lines to meet the needs of Essential Guide to Grinding in Mineral Processing JXSC2024年1月13日 Figure 1 Showing electrical energy and embodied energy for different types of tumbling mills Adapted from [2] Recently, it was realised that highgrade ores are depleting fast and are almost Grinding Media in Ball MillsA Review ResearchGate2023年7月4日 It has the advantages of simple structure, stable operation, high efficiency, energy saving, and convenient maintenance It is widely applied in the crushing and grinding of metal and nonmetallic ores The product particle size can be less than 5 mm or finerRoller Mill SpringerLink

The Advantages and Applications of Double Roll Crushers in Mining

2023年2月23日 This article explores the benefits and uses of double roll crushers in the mining industry It provides an indepth analysis of the components, operating principles, and various applications of double roll crushers Additionally, it compares the advantages and limitations of double roll crushers with other types of crushers commonly used in mining operations